Monitor-IoT-System

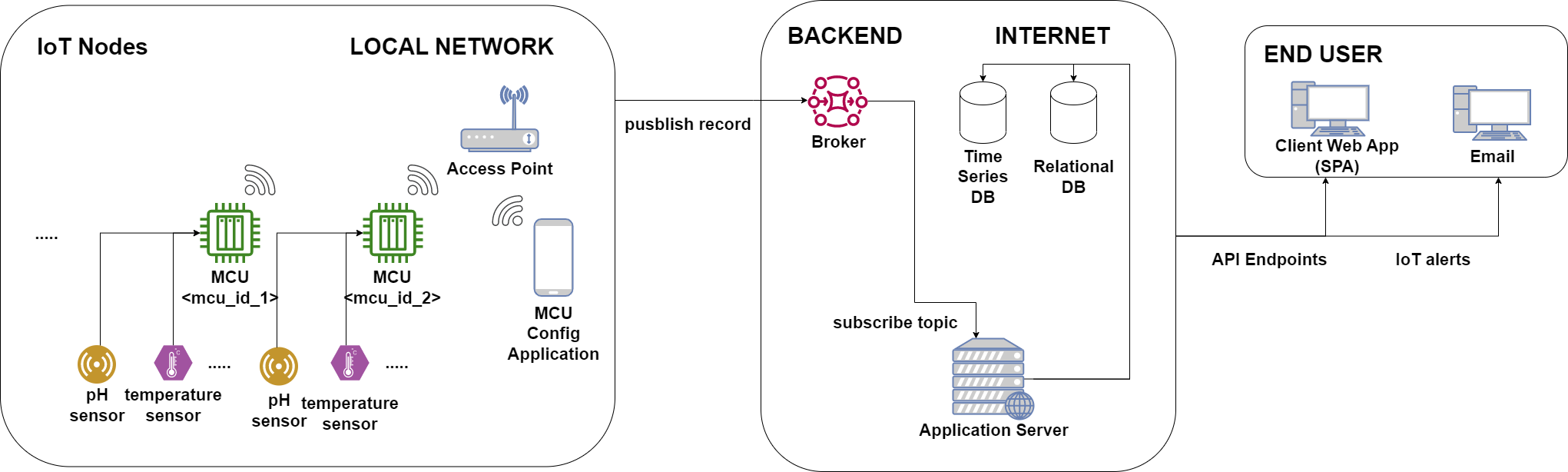

This project consists in the creation of a smart and automated system, using IoT technology, to enhance the efficiency, accuracy and safety in the pH industrial control process. By incorporating sensors, we can detect problems before they lead to costly downtime or safety hazards. The sensors collect data relative to the neutralization system’s environment. All this data is sent to a backend server, and through real-time data analysis, it identifies if the neutralization system is not working optimally. Finally, the data is made available to the user through a web application, where the user can see the data collected by the sensors and analyse it in a graphical format.

System Overview

The system is composed of the following components:

- IoT Sensor Node: collects the data from the neutralization device;

- Backend: receives and processes the data emitted by all the registered MCUs;

- Web Application: allows the user to register devices and analyse device-collected data.

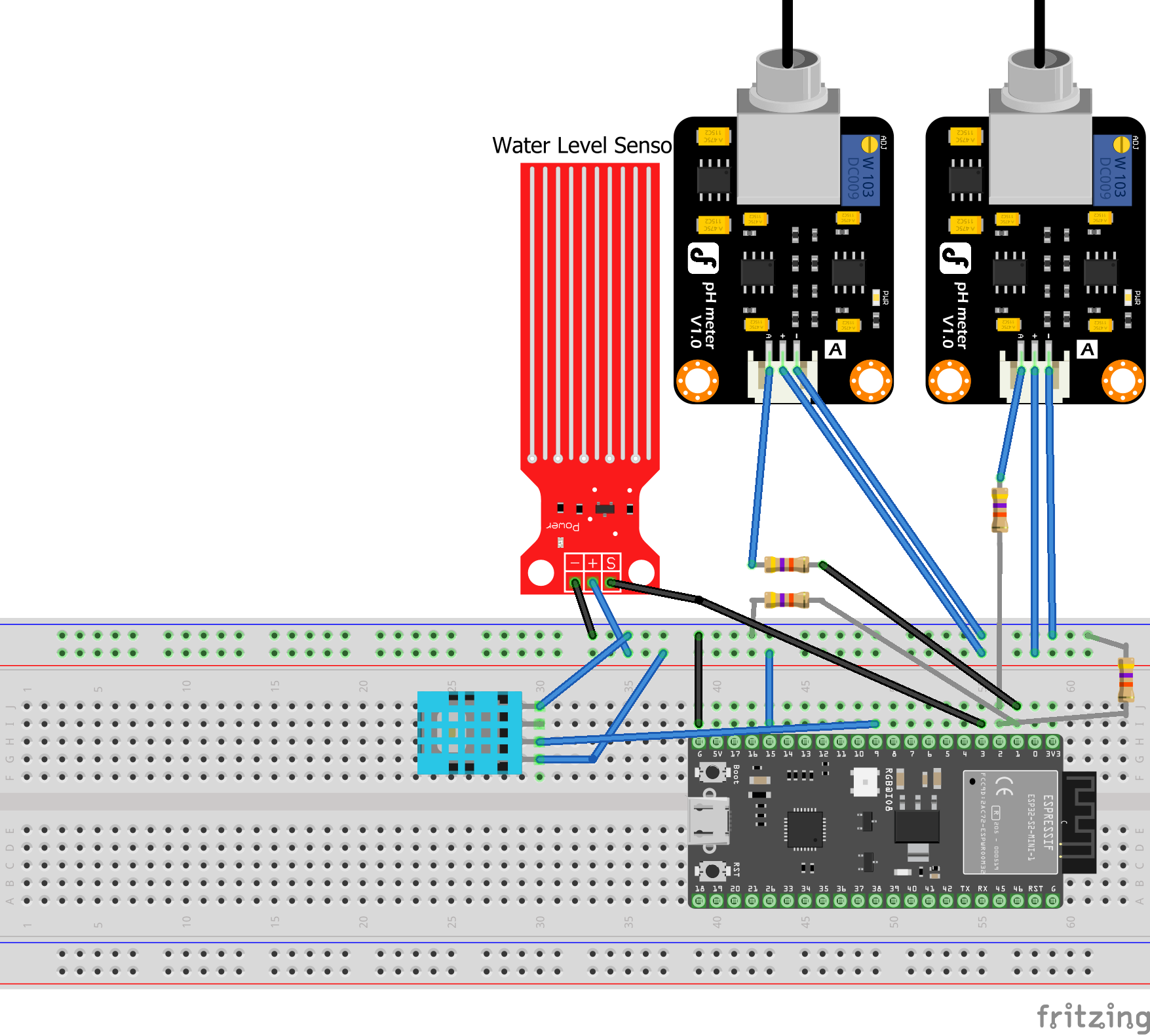

Hardware

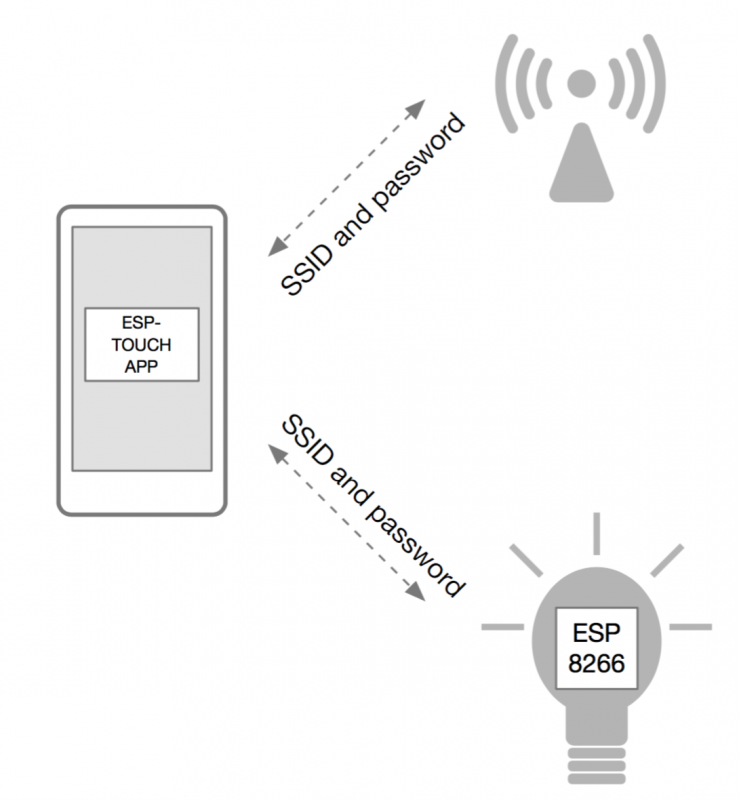

The system uses a built in Android app to configure the ESP-32, which is the microcontroller used in the IoT sensor node. The app allows the user to configure the WiFi network. The ESP-32 is connected to a pH sensor, a temperature sensor, and more.

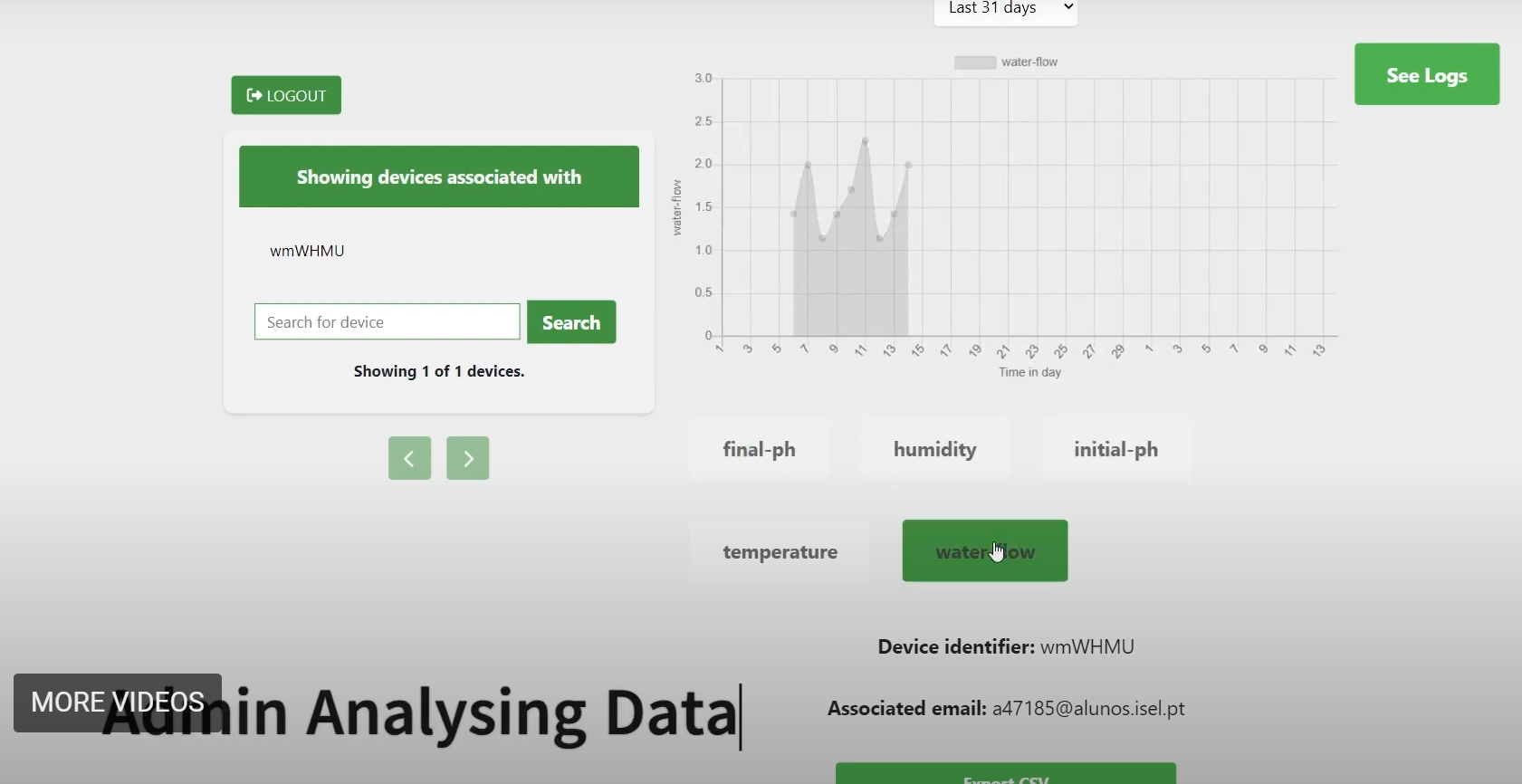

Website

The website is the main interface for the user to interact with the system. The user can register devices, see the data collected by the devices, and analyse the data.

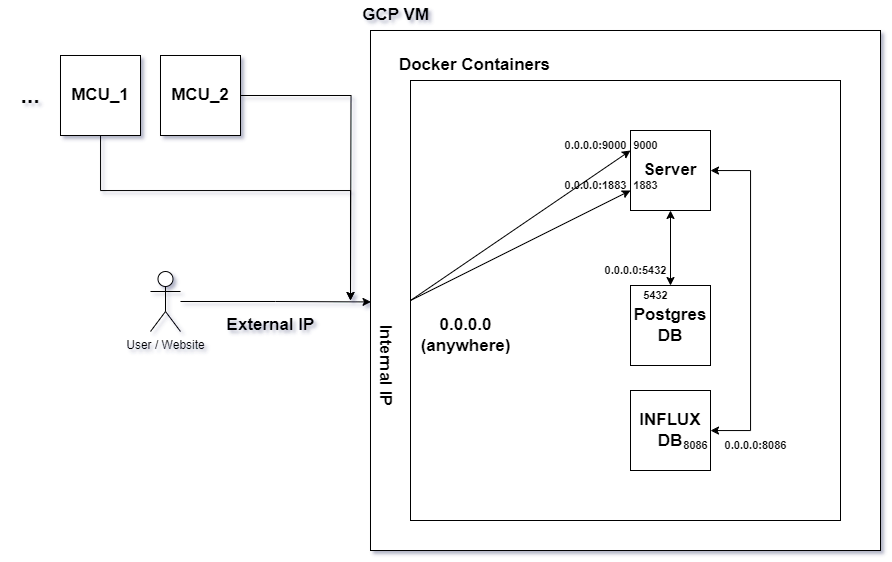

Deploy

The system uses Docker technology to deploy the backend and the web application. The server, which also serves the static content, the PostgreSQL database, and the InfluxDB, are all deployed in separate containers. This allows to scale all components independently.

Demo

Notice: This project was evaluated as 18/20.